Understanding the Mechanics of Automatic Transmission Work Systems

Exploring the intricacies of automotive mechanics reveals a fascinating labyrinth of components working in harmony. A critical aspect of this symphony is a system that orchestrates power delivery, enabling seamless travel while ensuring that energy is utilized efficiently. Grasping these complexities is essential for enthusiasts and professionals alike, as it directly correlates with enhancing vehicle efficacy and longevity.

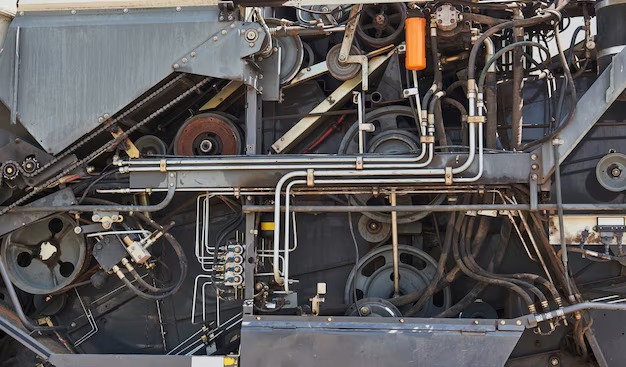

A deep dive into this area uncovers a variety of parts engaged in pivotal tasks, allowing operators to harness energy from their engines optimally. Each element contributes to an intricate interaction that ultimately determines how swiftly and smoothly automobiles can navigate diverse terrains. Recognizing these elements equips users with knowledge that can profoundly impact their driving experience.

Through meticulous examination and appreciation of these mechanisms, one can appreciate the underlying science that facilitates mobility. This understanding can aid in diagnosis and maintenance, contributing to safer and more pleasurable journeys on the road.

Basics of Vehicle Transmission Systems

This section introduces fundamental concepts related to shifting mechanisms in automobiles, emphasizing their role in translating power from the engine to the wheels. A proficient understanding of these systems is essential for enhancing the overall functionality and driving experience, as they ensure that the right amount of power reaches the wheels at an appropriate speed.

Types of Transmission Systems

Various kinds of shifting mechanisms exist, each with distinct characteristics and advantages. Below is a summary of the primary types commonly found in modern automobiles:

| Type | Description | Advantages |

|---|---|---|

| Manual | Requires driver input for gear selection. | Enhanced control, typically lower maintenance costs. |

| Automatic | Shifts gears automatically based on speed and engine load. | Ease of use, better for stop-and-go traffic. |

| CVT | Continuously variable transmission that offers seamless gear ratios. | Improved fuel efficiency, smoother acceleration. |

Key Components

Essential elements within shifting mechanisms play critical roles in efficient operation. Key components include gears, clutches, and torque converters, each contributing to the overall functionality. Recognizing how these parts interact can provide deeper insights into maintaining and optimizing transmission systems.

The Role of Gears in Performance

Gears serve as a fundamental component in altering the efficiency and response of a machine. Their configuration directly influences how power is transmitted from the engine to the wheels, allowing for variation in speed and torque. This intricate relationship impacts not just acceleration, but also fuel efficiency and overall driving experience.

Torque Multiplication

One of the primary functions of gears is to amplify torque. By adjusting the gear ratio, a higher torque can be supplied to the drivetrain, enabling the vehicle to overcome resistance and acceleration from a standstill. This phenomenon is particularly noticeable during uphill climbs or when heavy loads are involved. A well-optimized gear setup ensures that the engine performs at its peak within a specific rpm range, creating a balance between power delivery and fuel consumption.

Speed Regulation

In addition to managing torque, gears play a crucial role in regulating speed. Different gear ratios allow a vehicle to achieve various speed levels while maintaining efficiency. Lower gears are designed for increased torque at lower speeds, whereas higher gears facilitate cruising at faster speeds with reduced engine strain. This adaptability ensures that drivers can not only respond effectively in diverse driving situations but also enjoy smoother transitions between different speed ranges.

Types of Transmissions: Manual vs. Automatic

In modern automotive design, differing mechanisms play a crucial role in how power is transferred from the engine to the wheels. Each approach offers unique advantages and caters to diverse driving preferences. Understanding these variations can assist consumers in making informed decisions based on their requirements and driving style.

Manual Transmissions

Manual systems require drivers to engage gears through a physical shifter and clutch pedal. This direct interaction fosters a deeper connection between the driver and the car, allowing for precise control over gear changes and acceleration. Enthusiasts often favor this style for its engagement and potential for enhanced fuel efficiency when operated skillfully.

Automatic Transmissions

Automatic options, in contrast, provide a more leisurely experience by shifting gears without driver input. By employing complex systems of sensors and hydraulics, these designs offer ease and convenience, especially in stop-and-go traffic. Many contemporary models even feature adaptive technology that adjusts to driving habits, enhancing overall comfort and usability.

How Shifting Affects Fuel Efficiency

Shifting gears significantly influences the economy of fuel consumption in automotive machinery. Proper gear selection enables engines to operate within their ideal power bands, optimizing fuel usage. Strategies that focus on timing and method of shifting can lead to noticeable improvements in overall efficiency.

Engaging higher gears at the appropriate moments promotes lower engine RPMs, reducing the amount of fuel burned during travel. Conversely, lingering in lower gears may result in excessive fuel consumption, as the engine works harder than necessary. Drivers should be mindful of acceleration patterns and deceleration techniques, as these aspects directly impact how often shifts occur and the effect on fuel mileage.

Common Transmission Issues and Solutions

In the realm of automotive mechanics, certain challenges frequently arise that can impact driving efficiency and reliability. Recognizing these common complications and knowing appropriate remedies is essential for maintaining a smooth ride.

- Slipping Gears:

This situation occurs when the vehicle unexpectedly changes gears or loses power. Causes may include low fluid levels or worn components.

- Check and top off transmission fluid.

- Inspect for leaks in the system.

- Replace worn gears if necessary.

- Odor of Burning:

A burning smell can indicate overheating fluid or components. This could lead to severe damage if not addressed promptly.

- Examine fluid levels and quality.

- Cool down the system before checking components.

- If overheating persists, consult a professional mechanic.

- Fluid Leaks:

Visible fluid spots under the vehicle suggest a leakage issue. This can result in inadequate lubrication and subsequent damage.

- Identify the source of the leak.

- Repair or replace damaged seals or gaskets.

- Regularly monitor fluid levels and check for new leaks.

- No Response While Shifting:

If the car does not respond when attempting to change gears, it may signal a serious issue within the system.

- Inspect the linkages and cables for wear.

- Check the transmission fluid level and condition.

- Consider a diagnostic test for electronic components.

Addressing these prevalent concerns promptly can help ensure long-term reliability and longevity of a vehicle’s drivetrain. Regular maintenance and timely interventions can prevent minor issues from escalating into costly repairs.

Maintenance Tips for Optimal Operation

Ensuring longevity and efficiency in automotive systems requires regular attention and care. Adopting appropriate practices can greatly enhance functionality and reduce the likelihood of issues arising. A proactive approach is essential for maximizing reliability and performance.

Regular fluid checks and changes are crucial. Monitoring levels and conditions of engine oils, coolants, and other essential lubricants can prevent wear and tear. It’s advisable to follow manufacturer recommendations regarding intervals for fluid replacement.

Inspecting components periodically can reveal potential problems before they escalate. Pay special attention to belts, hoses, and filters, as these parts endure significant stress over time. Replacing worn-out items promptly can prevent more severe damage.

Ensure that seals and gaskets are in good condition to prevent leakages. Regular checks can help maintain optimal function and avert costly repairs. Addressing any signs of wear as soon as they appear will enhance system integrity.

Keep up with scheduled professional inspections. Skilled technicians can perform comprehensive evaluations and suggest necessary adjustments or repairs. Such services help in identifying subtle issues that may not be visible during routine checks.

Adhere to recommended practices when operating your equipment. Avoid excessive loads and abrupt starts or stops to prevent undue stress on mechanical parts. Proper driving techniques contribute significantly to overall health.

Lastly, staying informed about recalls or updates issued by manufacturers is beneficial. Participating in relevant programs can ensure your systems are operating with the most current enhancements and safety features.

Q&A: How the transmission works

What is the function of a planetary gearbox in automotive applications?

A planetary gearbox is designed to provide high torque and compact size, allowing for efficient power transmission in various automotive systems.

How does the ring gear operate within a planetary gearbox?

The ring gear serves as the outer gear in a planetary gearbox, providing a surface for the planet gears to rotate around, which helps achieve different gear ratios.

What role does hydraulic pressure play in the operation of a gearbox?

Hydraulic pressure is essential for engaging and disengaging gears within an automatic gearbox, enabling smooth transitions between different gear ratios.

How can you disengage a gear in a manual gearbox?

To disengage a gear in a manual gearbox, the driver must press the clutch pedal, which separates the flywheel from the gearbox, allowing for smooth shifting.

What is the relationship between the flywheel and the gearbox in an engine?

The flywheel connects to the engine’s crankshaft and helps maintain rotational momentum, while also providing a surface for the clutch to engage or disengage from the gearbox.

How does a planetary gearbox differ from other types of gearboxes?

A planetary gearbox features multiple gears rotating around a central sun gear, providing a more compact design and higher torque output compared to traditional gearboxes.

In what scenarios would you need to disengage the hydraulic system in a gearbox?

Disengaging the hydraulic system may be necessary during maintenance or repairs to prevent fluid leakage and ensure safe handling of gearbox components.

What advantages do hydraulic systems offer in modern gearboxes?

Hydraulic systems provide precise control over gear engagement and disengagement, allowing for smoother shifts and improved overall performance in automatic transmissions.

How does the configuration of a ring gear affect the performance of a planetary gearbox?

The configuration of the ring gear influences the gear ratio and torque output of the planetary gearbox, impacting its efficiency and suitability for specific applications.

What maintenance practices are essential for ensuring the longevity of a hydraulic gearbox?

Regularly checking hydraulic fluid levels, inspecting for leaks, and ensuring that all components, including the flywheel and ring gear, are free from wear and damage are crucial for maintaining a hydraulic gearbox.

What is the role of the sun gear in a planetary gear set within a car’s transmission?

The sun gear acts as the central gear in a planetary gear set, allowing it to rotate and transfer power to the planet carrier, which ultimately helps the car move.

How do traditional automatic transmissions differ from automated manual transmissions in terms of operation?

Traditional automatic transmissions use a hydraulic system to engage or disengage gears, while automated manual transmissions utilize sensors to determine when to shift between one gear and another.

What is the purpose of an automatic transmission in a vehicle?

The purpose of an automatic transmission is to transfer power from the engine to the wheels, allowing for smooth acceleration and deceleration without the need for manual gear shifting.

How does the valve body function inside the transmission?

The valve body controls fluid flow within the transmission, directing oil pressure to engage or disengage the clutches that change the gears based on the car’s speed and load.

What happens when the car slows down while in transmission in second gear?

When the car slows down in transmission in second gear, the hydraulic system adjusts the oil pressure to ensure that the transmission shifts smoothly to accommodate the lower output speed.

What are the three components essential for the operation of an automatic transmission?

The three components essential for the operation of an automatic transmission are the torque converter, valve body, and planetary gear set, which work together to transfer power from the engine to the output shaft.

How does a fluid coupling assist in the operation of an automatic transmission?

A fluid coupling allows for a smooth transfer of power from the engine to the transmission by using fluid dynamics, enabling the engine to run without directly engaging with the transmission when idle.

What does it mean when a car’s transmission allows the driver to select manual mode?

When a car’s transmission allows the driver to select manual mode, it enables them to manually shift through the set of gears, providing more control over acceleration and engine performance.

How does the housing of the torque converter contribute to the overall efficiency of a transmission?

The housing of the torque converter encases the fluid coupling mechanism, allowing it to efficiently transfer power from the engine to the transmission while minimizing slippage and maximizing torque delivery.

What is a common type of automatic transmission used in modern vehicles?

A common type of automatic transmission used in modern vehicles is the continuously variable transmission (CVT), which uses a belt or chain instead of traditional gearsets to provide seamless acceleration and optimal fuel efficiency.